I-Industrial Grinding I-Robot Arm Mechanical engu-6 ye-Axis Robot Arm ngenani Elincintisanayo Ingalo yerobhothi

I-Industrial Grinding I-Robot Arm Mechanical engu-6 ye-Axis Robot Arm ngenani Elincintisanayo Ingalo yerobhothi

Isigaba Esiyinhloko

Ingalo yerobhothi yezimboni/Ingalo yerobhothi esebenzisanayo / Isibambi sikagesi/Isicuphisi esihlakaniphile/Izixazululo zokuzenzakalela

Isicelo

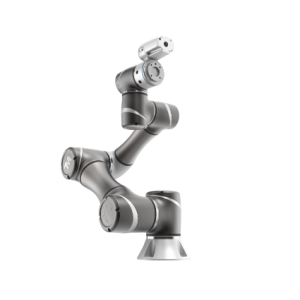

I-TM12 inokufinyelela okude kakhulu ochungechungeni lwethu lwamarobhothi, okuvumela ukusebenza ngokubambisana, ngisho nasezinhlelweni ezidinga ukunemba kwezinga lemboni namandla okuphakamisa. Inezici eziningi ezivumela ukuthi isetshenziswe ngokuphepha eduze kwezisebenzi zabantu, futhi ngaphandle kwesidingo sokufaka imigoqo emikhulu noma uthango. I-TM12 iyisinqumo esihle kakhulu se-cobot automation ukuthuthukisa ukuguquguquka, nokwandaukukhiqiza.

Ngohlelo lombono oluhamba phambili ekilasini, ubuchwepheshe be-AI obuthuthukisiwe, ukuphepha okuphelele, nokusebenza okulula,I-AI Cobot izoyisa ibhizinisi lakho phambili kunangaphambili.Thatha i-automation uye ezingeni elilandelayo ngokuthuthukisa ukukhiqiza, ukuthuthukisa ikhwalithi, nokunciphisa izindleko.

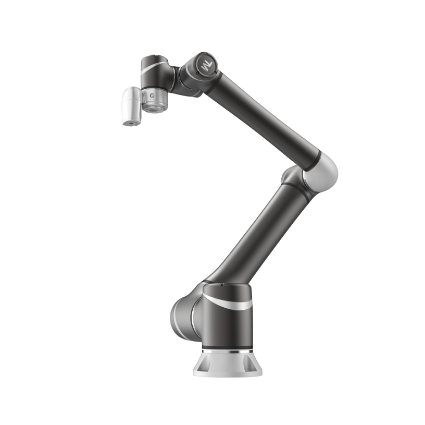

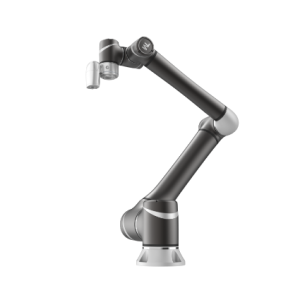

Sethula ukusungula kwethu kwakamuva emkhakheni we-industrial automation - I-Industrial Grinding and polishing Robot Arm Mechanical 6-Axis Robot Arm. Idizayinelwe ukuguqula imisebenzi yokugaya nokupholisha ezimbonini zonkana, le ingalo yerobhothi ethuthukisiwe iletha ukunemba okuphezulu, ukusebenza kahle kanye nokuguquguquka.

Ingalo yethu yerobhothi inezimbazo eziyisithupha zokunyakaza, ilingisa ukuguquguquka nokujula kwengalo yomuntu, eyivumela ukuthi yenze imisebenzi eyinkimbinkimbi yokugaya nokupholisha kalula. Leli zinga lokuqondisa liqinisekisa ukuthi yonke indawo iphathwa ngokulinganayo, okuholela ekuqedeni okuhle nekhwalithi.

Okunye okugqama kakhulu kwezingalo zethu zamarobhothi okugaya nokupholisha izingalo amandla azo amangalisayo okusebenza. Idizayinelwe ukumelana nokusetshenziswa okuqinile kwezimboni, lengalo yerobhothi ingakwazi ukuphatha imithwalo esindayo futhi imelane nezimo zokusebenza ezinzima. Isakhiwo sayo esiqinile siqinisekisa ukuzinza ngesikhathi sokusebenza, kunciphisa ukudlidliza okungase kuthinte ukunemba kwemishini.

Akukhona nje kuphela ukuthi lengalo yerobhothi inamandla, ijubane layo nokunemba nakho kuyahlaba umxhwele. Ifakwe ama-algorithms athuthukisiwe okulawula ukunyakaza, ingafinyelela ukusebenza okushesha kakhulu ngaphandle kokuthikameze ukunemba. Lokhu kwenza imisebenzi yokugaya nokupholisha ukuthi iqedwe ngokushesha, okwandisa kakhulu umkhiqizo enqubweni yokukhiqiza.

Ukuze kuthuthukiswe ukuguquguquka kwayo nokuvumelana nezimo, izingalo zethu zerobhothi zingahlelwa kalula futhi zimiswe kabusha ukuze zenze amasu ahlukahlukene okugaya nokupholisha. Noma ngabe ukugaya imiphetho ebukhali, ukupholisha izindawo ezithambile, noma ukupholisha amaphethini ayinkimbinkimbi, lengalo yerobhothi ingakwenza konke.

Izingalo zethu zerobhothi ezigayayo nezizipholizayo zihlinzeka ngokuhlanganiswa okungenamthungo namanye amasistimu nemishini ezishintshayo. Lokhu kuvumela ukuhamba komsebenzi okungenazihibe, kuqede amabhodlela futhi kuthuthukise ukukhiqiza okuphelele.

Ukwengeza, amanani ethu ancintisanayo aqinisekisa ukuthi amabhizinisi abo bonke osayizi angazuza kulobu buchwepheshe obusezingeni eliphezulu ngaphandle kokuphula ibhange. Sikholelwa ukuthi okuzenzakalelayo kufanele kufinyeleleke kuwo wonke umuntu, futhi imikhiqizo yethu ihlanganisa lokhu kuzibophezela ekuthengeni.

Kafushane, i-Industrial Grinding and Polishing Robot Arm Mechanical 6-Axis Robot Arm iwushintsho lomdlalo emkhakheni we-automation yezimboni. Ngamandla ayo okusebenza aphakeme, isivinini, ukunemba, ukuguquguquka kanye nentengo yokuncintisana, lengalo yerobhothi izoguqula ukusebenza kokugaya nokupholisha kuzo zonke izimboni. Yamukela ikusasa lezinto ezishintshayo zezimboni futhi ujabulele amazinga amasha okukhiqiza nokuvumelana nemikhiqizo yethu ephumelelayo.

Izici

I-SMART

Ubufakazi besikhathi esizayo Ikhobothi Yakho nge-AI

• Ukuhlola okuzenzakalelayo (AOI)

• Ukuqinisekiswa kwekhwalithi nokuvumelana

• Ukwandisa ukusebenza kahle kokukhiqiza

• Yehlisa izindleko zokusebenza

OKULULA

Asikho isipiliyoni esidingekayo

• Isikhombikubona sokuqhafaza ukuze kube lula ukuhlela

• Ukugeleza kokuhlela okugxile kwinqubo

• Isiqondiso esilula sesandla sokufundisa izikhundla

• Ukulinganisa okubonakalayo okusheshayo ngebhodi lokulinganisa

KUPHEPHILE

Ukuphepha ngokubambisana kuyinto ehamba phambili yethu

• Ihambisana ne-ISO 10218-1:2011 & ISO/TS 15066:2016

• Ukutholwa kwe-Collison ngesitobhi esiphuthumayo

• Yonga izindleko nendawo yezithiyo nokubiya

• Misa imikhawulo yesivinini endaweni yokusebenza ngokubambisana

Ama-cobot anamandla e-AI abona ubukhona nokuma kwemvelo yawo kanye nezingxenye ukuze enze ukuhlola okubonakalayo kanye nemisebenzi yokukhetha nendawo eguqukayo. Sebenzisa kalula i-AI emugqeni wokukhiqiza futhi ukhuphule umkhiqizo, wehlise izindleko, futhi ufinyeze izikhathi zomjikelezo. Umbono we-AI ungafunda nemiphumela evela emishinini noma emishinini yokuhlola futhi wenze izinqumo ezifanele ngokufanele.

Ngaphandle kokuthuthukisa izinqubo zokuzenzakalela, i-cobot eshayelwa yi-AI ingakwazi ukulandelela, ihlaziye, futhi ihlanganise idatha ngesikhathi sokukhiqiza ukuze ivimbele amaphutha futhi ithuthukise ikhwalithi yomkhiqizo. Thuthukisa kalula ukusebenza kwemboni yakho ngesethi ephelele yobuchwepheshe be-AI.

Amarobhothi ethu asebenzisanayo afakwe uhlelo lokubona oludidiyelwe, olunikeza ama-cobot ikhono lokubona indawo ewazungezile ethuthukisa kakhulu amandla e-cobot. Umbono werobhothi noma ikhono “lokubona” nokuhumusha idatha ebonakalayo ibe yimiyalo ingenye yezici ezisenza sibe ngcono. Iwukushintsha umdlalo wokwenza imisebenzi ngokunembile ezindaweni zokusebenza ezishintshayo, okwenza imisebenzi ihambe kahle, nezinqubo zokuzenzakalela zibe nempumelelo.

Idizayinelwe kucatshangwa ngabasebenzisi bokuqala, ulwazi lokuhlela akuyona imfuneko ukuze uqalise nge-AI Cobot. Ukunyakaza kokuchofoza bese uhudula okunembile usebenzisa isofthiwe yethu yokugeleza kwezinhlelo kunciphisa ubunzima. Ubuchwepheshe bethu obunelungelo lobunikazi buvumela ama-opharetha angenawo umuzwa wokubhala amakhodi ukuhlela iphrojekthi emfushane njengemizuzu emihlanu.

Izinzwa zokuphepha ezingokwemvelo zizomisa i-AI Cobot uma kutholwa ukuthintana ngokomzimba, kunciphise umonakalo ongaba khona wendawo engenawo ukucindezela nephephile. Ungakwazi futhi ukumisa imikhawulo yesivinini irobhothi ukuze lisetshenziswe ezindaweni ezihlukahlukene eduze kwabasebenzi bakho.

Imikhiqizo Ehlobene

Ipharamitha yokucaciswa

| Imodeli | TM12 | |

| Isisindo | 32.8KG | |

| Ubukhulu benkokhelo | 12KG | |

| Finyelela | 1300 mm | |

| Amabanga Ahlangene | j1,j6 | ±270° |

| J2, J4, J5 | ±180° | |

| J3 | ±166° | |

| Isivinini | J1, J2 | 120°/s |

| J3 | 180°/s | |

| J4 | 180°/s | |

| J5 | 180°/s | |

| J6 | 180°/s | |

| Isivinini Esijwayelekile | 1.3m/s | |

| Ubukhulu. Isivinini | 4m/s | |

| Ukuphindaphinda | ± 0.1mm | |

| Izinga lenkululeko | 6 ukuzungeza amalunga | |

| I/O | Ibhokisi lokulawula | Okokufaka kwedijithali:16 Okukhiphayo kwedijithali:16 Okokufaka kwe-analogi:2 I-analogue ephumayo:1 |

| Ithuluzi Conn. | Okokufaka kwedijithali:4 Okukhiphayo kwedijithali:4 Okokufaka kwe-analogi:1 Okuphumayo kwe-analog:0 | |

| I/O Power Supply | I-24V 2.0A yebhokisi lokulawula kanye ne-24V 1.5A yethuluzi | |

| I-IP Classification | IP54(Ingalo Yerobhothi); IP32(Ibhokisi Lokulawula) | |

| Ukusetshenziswa kwamandla | Ama-watts angu-300 ajwayelekile | |

| Izinga lokushisa | Irobhothi lingasebenza ebangeni lokushisa elingu-0-50℃ | |

| Inhlanzeko | ISO Class 3 | |

| Ukunikezwa kwamandla kagesi | 100-240 VAC, 50-60 Hz | |

| I/O Interface | 3xCOM, 1xHDMI, 3xLAN, 4xUSB2.0, 2xUSB3.0 | |

| Ukuxhumana | I-RS232, i-Ethemet, i-Modbus TCP/RTU (inkosi nesigqila), i-PROFINET (Uma uthanda), i-EtherNet/IP(Uma uthanda) | |

| Imvelo yokuhlela | I-TMflow, i-flowchart isekelwe | |

| Isitifiketi | I-CE, SEMI S2 (Inketho) | |

| I-AI nombono*(1) | ||

| Umsebenzi we-AI | Ukwahlukaniswa, Ukutholwa Kwento, Ukuhlukaniswa, Ukutholwa Okungaqondakali, I-AI OCR | |

| Isicelo | Ukuma, ukufundwa kwebhakhodi ye-1D/2D, i-OCR, ukutholwa kokukhubazeka, ukukala, ukuhlola komhlangano | |

| Ukunemba Kokumisa | Ukuma kwe-2D: 0.1mm*(2) | |

| Iso Esandleni (Lakhelwe ngaphakathi) | Ikhamera yombala egxile ngokuzenzakalela enokulungiswa okungu-5M, Ibanga lokusebenza 100mm ~ ∞ | |

| Iso nesandla (Ongakukhetha) | Sekela Amakhamera aphezulu angu-2xGigE 2D noma i-1xGigE 2D Ikhamera +1x3D Ikhamera*(3) | |

| *(1)Azikho izingalo zamarobhothi ezakhelwe ngaphakathi i-TM12X, TM14X, TM16X, TM20X nazo ezitholakalayo. *(2)Idatha kuleli thebula ikalwa ngelebhu ye-TM futhi ibanga lokusebenza liyi-100mm. Kufanele kuqashelwe ukuthi kuzinhlelo zokusebenza ezingokoqobo, amanani ahambisanayo angase ahluke ngenxa yezinto ezifana nomthombo wokukhanya okukusayithi, izici zento, nezindlela zokuhlela zombono ezizothinta ushintsho ekunembeni. *(3)Bheka iwebhusayithi esemthethweni ye-TM Plug & Play ukuze uthole amamodeli ekhamera ahambisana ne-TM Robot. | ||

Ibhizinisi Lethu